This first-of-its-kind electric SA minibus taxi used to be powered by petrol

Share

Researchers have converted a fossil fuel-powered minibus taxi to an electric vehicle – the first of its kind.

The minibus can travel at a maximum speed of 120km/h and can be charged efficiently in just over two hours.

Retrofitting the 250 000 minibuses in the country will be cheaper and more environmentally friendly than importing new vehicles.

For climate change news and analysis, go to News24 Climate Future.

The first-of-its-kind electric minibus taxi – which was converted from a petrol-powered vehicle – has been completed and will soon hit the streets after being tested for road safety.

The project is a collaboration between researchers at Stellenbosch University and Rham Equipment and is sponsored by the South African National Energy Development Institute.

Retrofitting or converting a petrol or diesel minibus to an electric vehicle is considered a cheaper option than importing new vehicles, explained Professor Thinus Booysen of the Department of Industrial Engineering at the university.

According to Booysen:

More than 70% of the trips in South Africa are by minibus in the informal sector, which is why we are hoping to encourage the retrofitting of some of the 250 000 minibuses in the country with electric propulsion. These will be cheaper and much more environmentally friendly than new electric vehicles.

The prototype – which was recently completed and is operational – will be used to prove the concept. It is currently being tested for road safety, and then its performance will be tested.

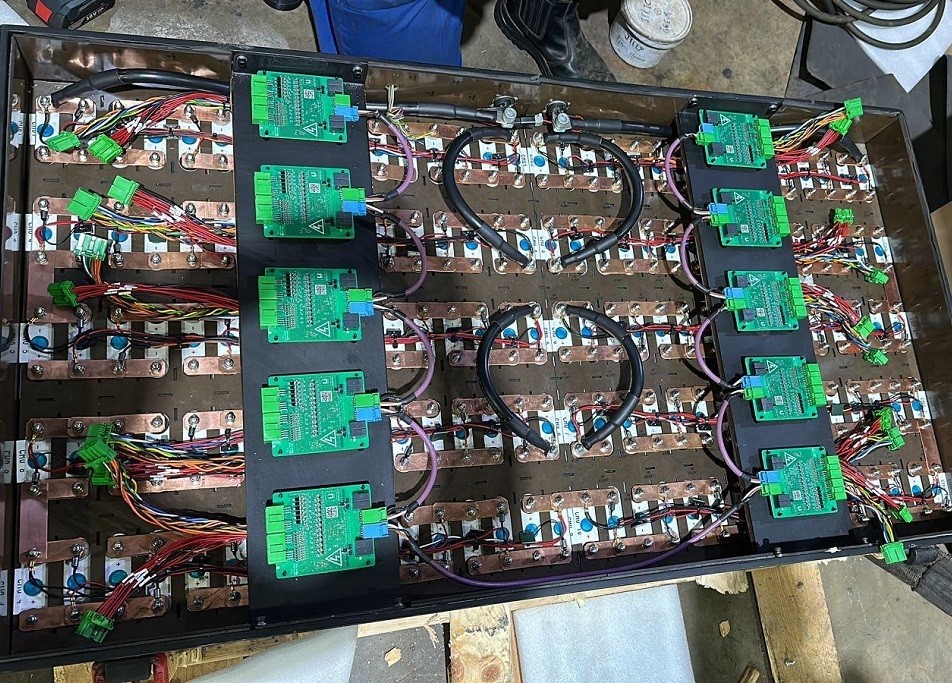

To retrofit the minibus, its internal combustion engine and petrol tank, gas pipe and radiator were among the equipment removed. It was then fitted with a “kit” developed by the Stellenbosch University researchers and Rham, which consists of an electric motor, inverter, charger, and other equipment to power it with electrical energy, explained Stephan Lacock, a student at Stellenbosch University who is completing his master’s degree in electronic engineering.

Lacock helped design and retrofit the minibus with partners at Rham Equipment.

Lacock noted that the retrofit had to comply with national road safety regulations – this includes not making permanent changes to the minibus chassis – which is the base frame of the car.

The taxi was fitted with an electric motor, inverter, charger and other equipment to power it with electrical energy.

The taxi was fitted with an electric motor, inverter, charger and other equipment to power it with electrical energy.

Supplied Thinus Booysen, Stellenbosch University

READ | OPINION | The automotive industry is ready and waiting to advance new energy vehicles in SA

The vehicle is able to harness the energy that is created when going downhill or slowing down – which makes it energy efficient.

“As a result, the minibus is now equipped to travel an estimated range of approximately 120km, with a maximum speed of 120km/h. It has an electric motor power of 90kW and a battery capacity of 53.76kWh.

“This ensures that it meets all load and driving requirements comparable to those of traditional internal combustion engine minibuses,” said Lacock.

“Thanks to the inclusion of a 20kW charger, the minibus can be efficiently charged in just over two hours,” he added.

With more iterations and changes in technology, the performance of these vehicles is expected to improve – such as having quicker charging times and being able to travel over longer ranges.

‘Slay a grid on its knees’

A concern about the shift to electric vehicles – and powering the retrofitted taxis – is that it would add a load to the already constrained grid, noted Booysen.

“We need to look at what the impact would be if we add an extra load of electric vehicles to the grid. Given that people who can buy electric vehicles can also afford to install fast charges, the impact of those vehicles will quickly slay a grid already on its knees,” said Booysen.

Unlike petrol and diesel vehicles, which have easily accessible fuel stations and can refill instantly, electric minibuses require a longer time to charge and the energy source is limited, he added.

PhD student Johan Giliomee similarly pointed out that the expected charging times of the minibuses is a concern – given the additional load that charging places on the grid. “Research results show that electrifying all minibus taxis in South Africa could add a load of 5% of what the grid can currently deliver,” said Giliomee.

Taxis operate during peak times – before and after the workday, and their charging times will similarly correlate. “This will result in a significant peak power draw that needs to be accounted for when planning for the electrification of the minibus taxi sector,” said Giliomee. Further analysis is required to determine the total energy required to power these taxis for operations.

Giliomee suggested that minibuses be powered with electricity from solar panels and battery energy storage systems at taxi ranks. Hydrogen could also be an alternative power source or storage solution.

“The vast majority of taxis are stationary between the early morning and afternoon peaks, making it an ideal opportunity for charging from solar panels. This also means a single charge would only need to supply sufficient energy for half the day, significantly reducing the required battery capacity…” said Giliomee.

Other ideal opportunities for charging would be overnight when the electricity demand is at its lowest.

Booysen said that another project is looking into the impact of electric minibuses feeding back power to the grid.

The taxi was fitted with an electric motor and gea

The taxi was fitted with an electric motor and gearbox also known as the drivetrain. This is connected to a custom-designed battery pack.

Supplied Thinus Booysen, Stellenbosch University

This innovation is expected to help build the skills needed to manufacture electric vehicles domestically. South Africa’s automotive industry contributes 4.9% to GDP – of this, 2.9% is attributed to manufacturing and 2% from retail, according to the National Association of Automobile Manufacturers of SA (Naamsa).

Europe is one of South Africa’s main markets for vehicle exports, but the EU is looking to ban fossil fuel-powered vehicles from 2035, posing a risk to the domestic industry.

“Remaining in the slow lane of the electric vehicle transition could put thousands of jobs at risk,” said Booysen.

Retrofitting this single minibus required up to three engineers and artisans, all bringing different skill sets – some worked on electronics and others on mechanical components, explained Lacock.

Apart from the delays in getting imported parts, Lacock said that the physical work time took about a month. There was a lot of learning, trials and testing as the retrofit happened. With the kit that was developed through the retrofitting process of the first model, future retrofits could be as quick as one day.

Lacock added that this project could make others aware of how retrofitting the minibuses works, and hopefully, more people will be interested in doing it. If the project is scaled then it could create jobs for two to three people per vehicle, per month.

“Rham Equipment is using entirely local skills and people to assemble everything – from battery packs to the mechanical implementation of the drive train. This enables us to build local skills,” said Lacock.

The next phase of the project is to retrofit a bus – this is a collaboration with Rham and Golden Arrow Bus Service, said Booysen.

Source: https://www.news24.com/fin24/